|

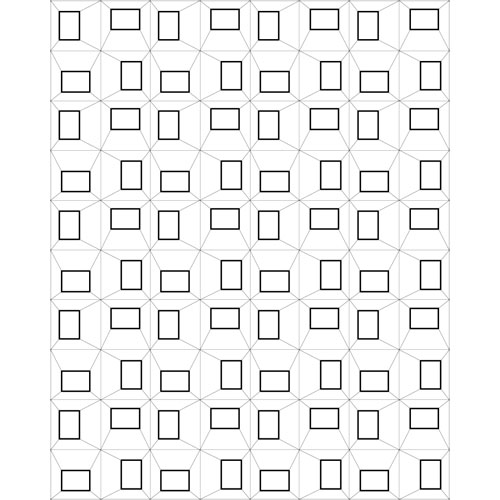

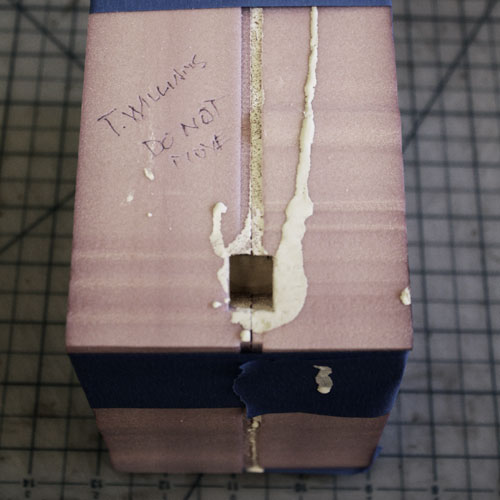

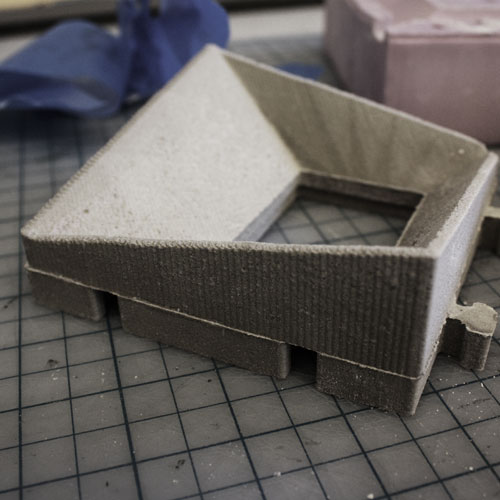

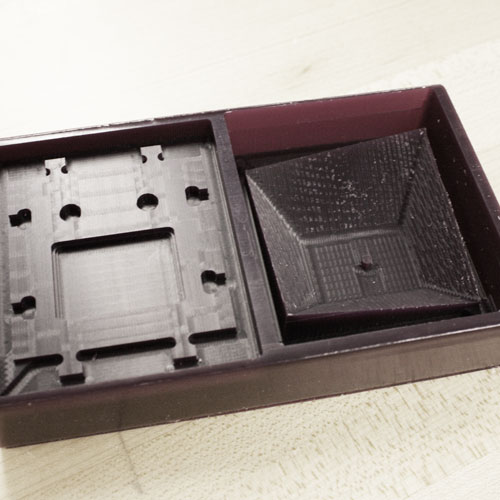

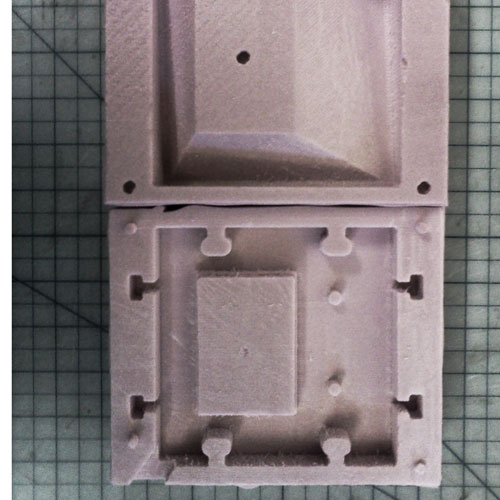

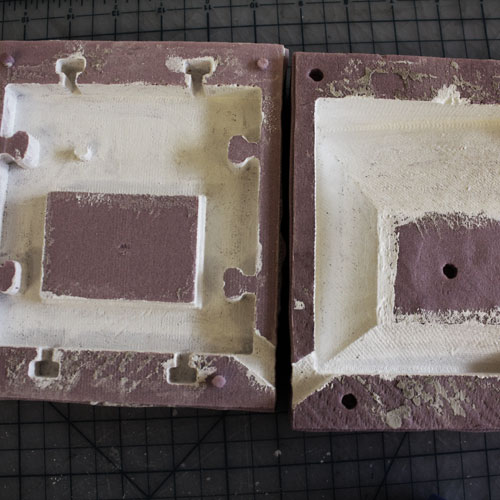

After some initial troubles with the table-top mill, I decided to scale the part by 2 and try milling it out of foam on the shopbot CNC router. This image shows the surfaces before their finishing pass. |

|

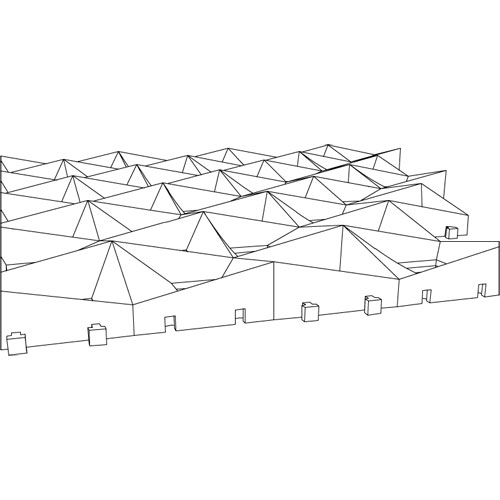

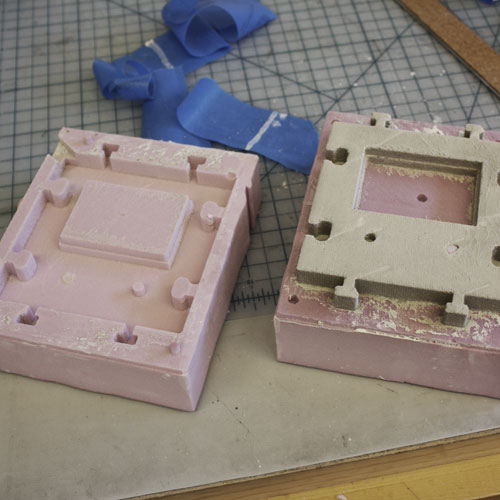

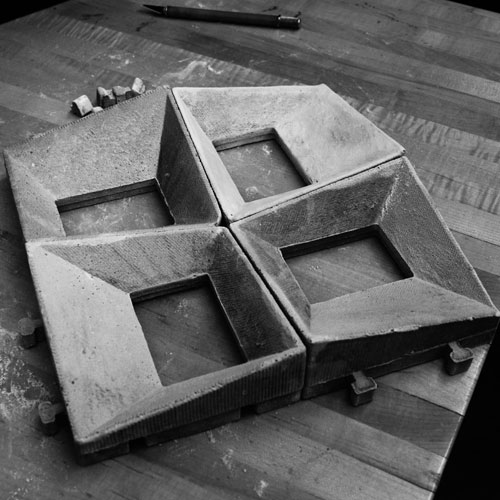

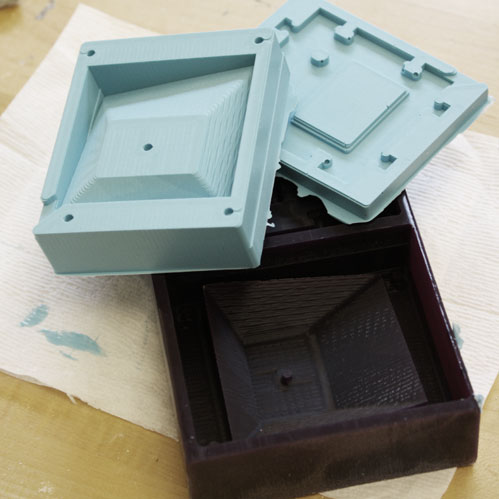

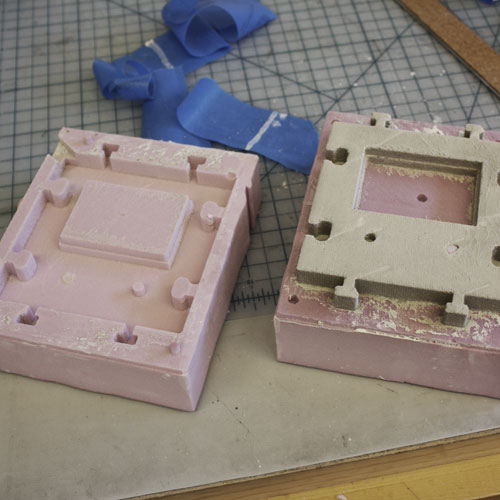

Final Molds. For the foam process, I milled the mold directly out of the foam. Unlike the wax process where we mill a positive, cast a flexible mold, and then use the flexible mold for all future casting. |

|

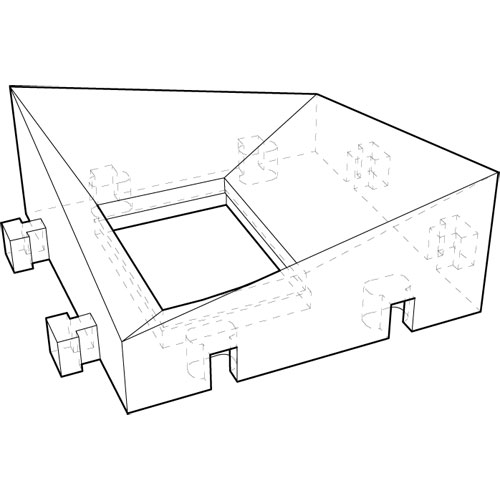

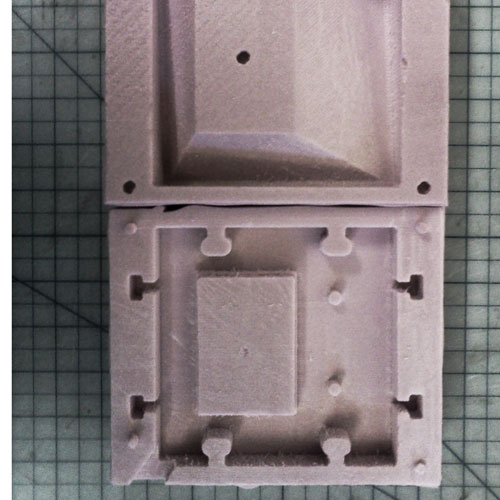

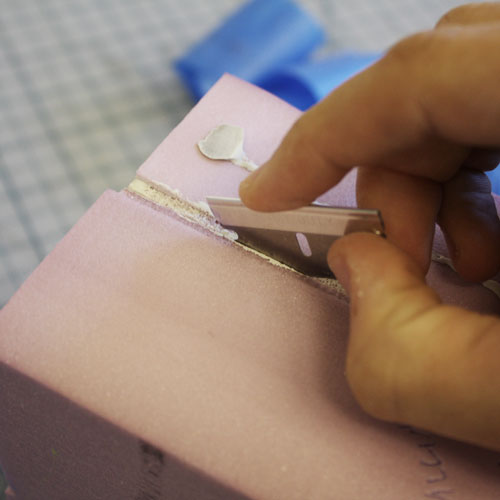

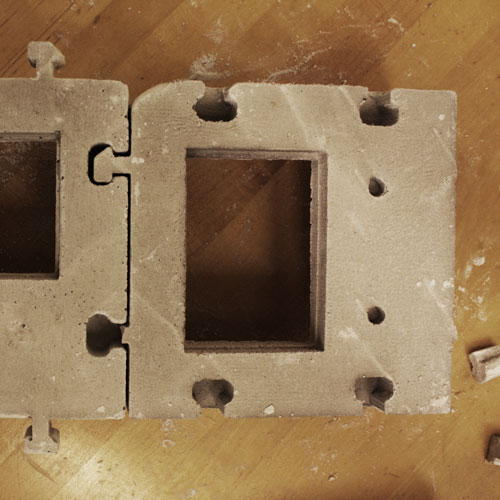

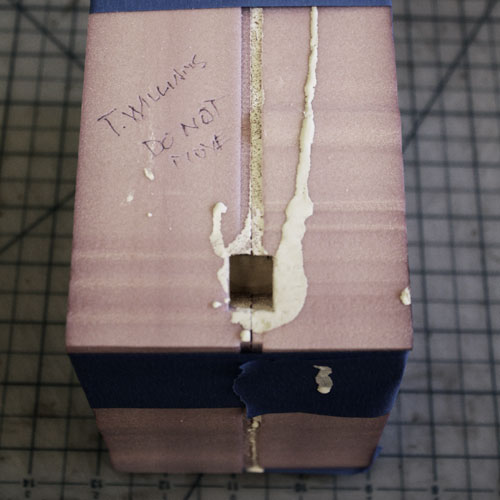

For the first cast, I used a releasing agent, but no gesso and it was very hard to remove the mold. |

|

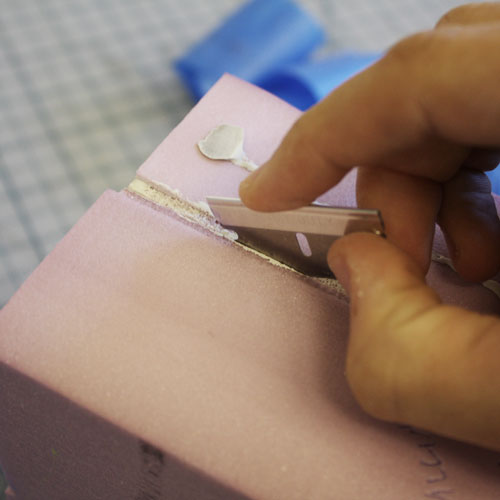

It took me about 20 minutes to get the mold off the part. I had to resort to prying with a razor blade. This damaged the mold some, but in the end not too bad. |

|

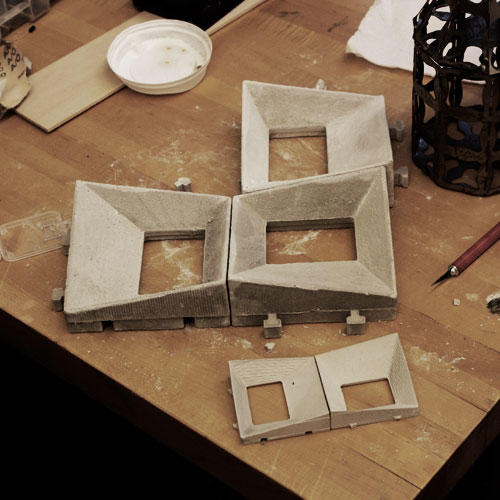

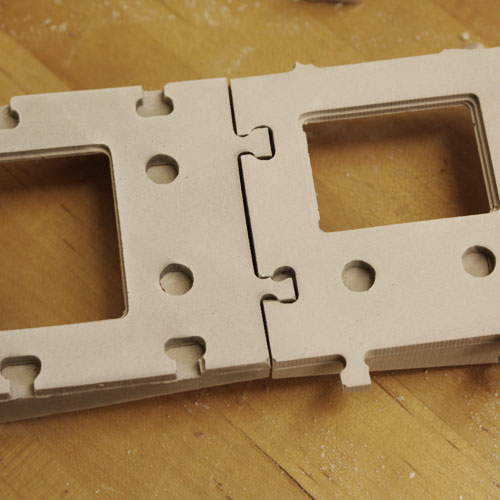

One of the nail holes in the back of the part was still filled with the foam from the mold when I finally pulled it apart. A combination of a poor choice of geometry and a lack of an

effective releasing strategy. This meant that the first piece I cast was the only one that would be able to hang from the wall. |

|

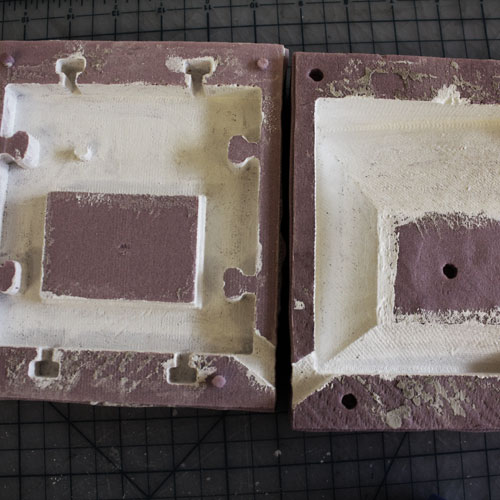

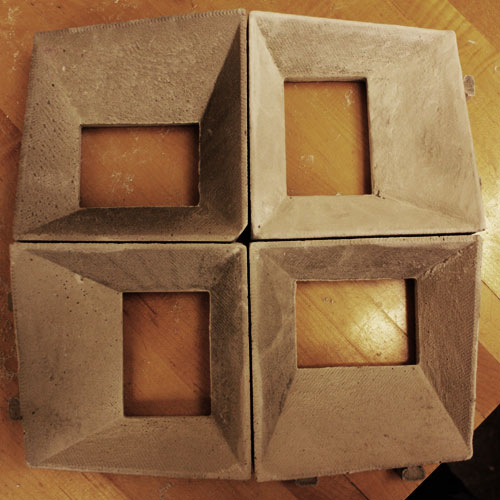

So, for the next pass, I gesso'd the mold AND used a spray releasing agent. |

|

The gesso made a huge difference, but eventually the poor design of the part's geometry caused some irreparable damage to the foam. I managed to get four parts made before the mold failed. |

|

|